The Importance of NAC Software for the Manufacturing and Industrial Sector

With the digitalization of manufacturing processes, network security has become a critical need in the manufacturing and industrial sectors. Network Access Control (NAC) software protects production lines, industrial devices, and corporate data, ensuring business continuity.

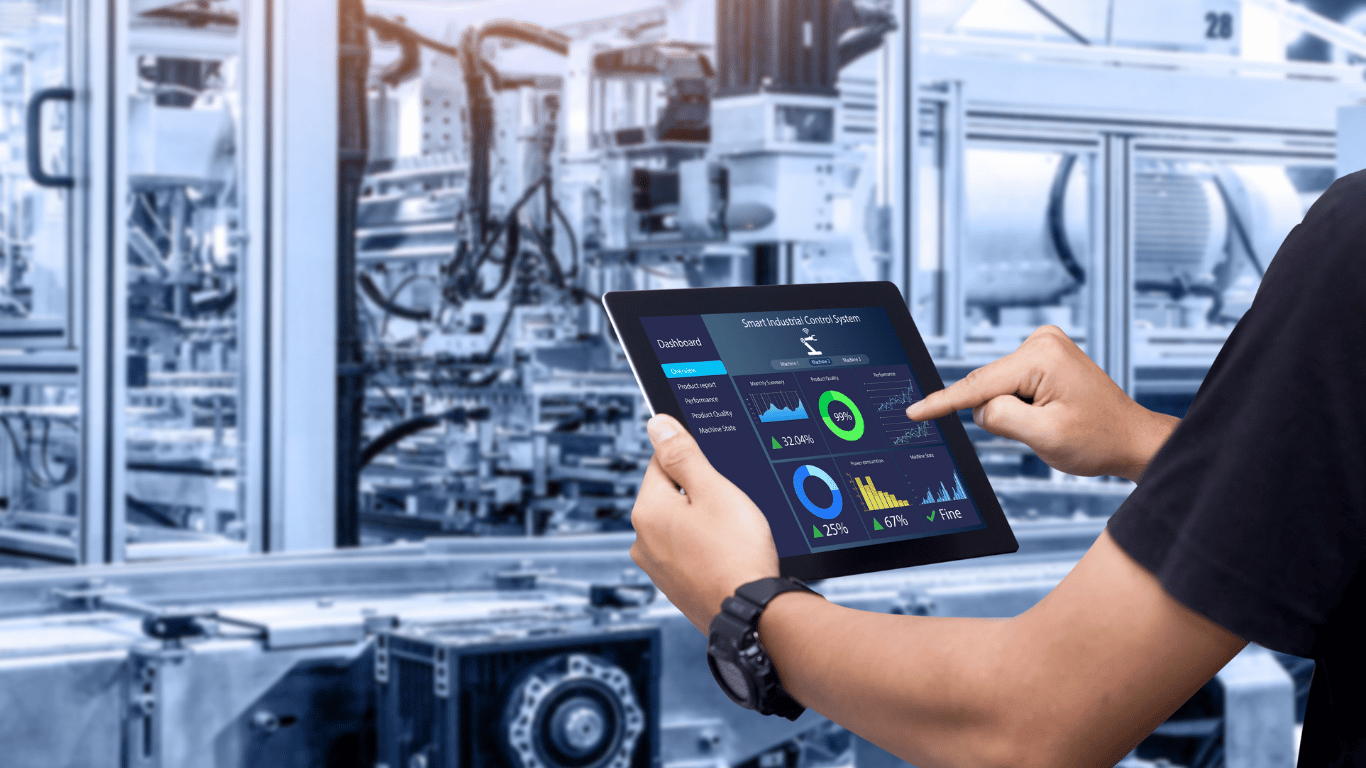

Security of Industrial IoT (IIoT) Devices

Machines, sensors, and automation systems used in manufacturing plants are often connected to the internet and, therefore, fall under the scope of Industrial IoT (IIoT). However, these devices may not be fully compatible with traditional antivirus and security solutions and can have serious security vulnerabilities, such as weak passwords or outdated firmware.

NAC (Network Access Control) software automatically detects these devices as they connect to the network, authenticates them, and grants access only to authorized systems. Devices posing security risks are automatically isolated from the network, thus preserving the integrity of the production network.

Protecting Production Continuity

Downtime on production lines can lead to significant financial losses in a short period, and one of the main reasons for these interruptions is cyberattacks. Network Access Control (NAC) solutions monitor abnormal behavior within the network in real-time and automatically quarantine suspicious devices when detected. This prevents production line disruptions, ensures operational continuity, and helps avoid potential financial losses.

Secure Management of Visitor and Contractor Access

Manufacturing plants often integrate external service providers, maintenance teams, and subcontractors into their networks, which can create a potential security vulnerability. Thanks to Network Access Control (NAC) software, access for external users is limited to specific network segments, and visitor connections are managed in a temporary and controlled manner. This control mechanism minimizes both internal and external threats, ensures network security, and helps protect the manufacturing facility.

Security and Performance Enhancement with Network Segmentation

Network Access Control (NAC) solutions divide the network into logical segments, isolating production, office, and guest networks from each other. This ensures that security issues occurring in one area do not spread to other areas, preserving the overall security of the network.

Additionally, critical production traffic is isolated from unnecessary network loads and works more efficiently and quickly. This segmentation enhances both network security and performance, thus increasing operational efficiency for businesses.

Regulatory Compliance and Reporting Capabilities

The manufacturing sector is subject to many security standards and legal regulations such as ISO 27001, NIST, and others. Network Access Control (NAC) software records network access in detail and generates transparent reports that can be used in audits. It also detects non-compliant devices and automatically isolates them, preventing security breaches. These features enable companies to fulfill their legal obligations and simplify audit processes, ensuring compliance effectively.

In conclusion, Network Access Control (NAC) software in the manufacturing and industrial sectors is not just a network security tool; it is a strategic solution that enhances production efficiency, ensures business continuity, and protects critical infrastructures. An investment in NAC provides strong defense against cyber threats and makes the digital transformation process secure.